Transportation of lithium batteries by sea, air and land

Today, widely used in electric vehicles, electric bicycles, power tools, mobile phones and a huge range of consumer electronics, lithium batteries offer an excellent combination of performance, lightness and efficiency and price.

Many people think that the transportation of lithium batteries is safe, but unfortunately they are wrong. You can't just put them in a box and send them, because there are a number of international laws and regulations that ensure the safety of those who transport them.

While the delivery of new batteries as part of the products is relatively safe (although regulated by strict rules), the return of damaged or used batteries for repair, recycling or disposal poses a serious risk.

With the continued growth of the market for products using lithium batteries as power sources, the risk associated with their transportation is also increasing (sales of electric vehicles are expected to grow over the next decade and beyond), this increased risk has forced regulators to act and they have developed a number of rules governing the transportation and packaging of batteries.

In order to understand how to transport and what to pack lithium-ion batteries during transportation, you need to refer to the UN regulations (in particular, UN3480, UN 3481 and UN3090, UN3091), as well as the rules established by various transport authorities (including IATA - the International Air Transport Association).

- SDS(MSDS) - Product safety data sheet

- UN 38.3 Test Summary Report- Summary data confirming that the batteries have been tested for compliance with UN 38.3 safety requirements

- Сertificate for safe transport of goods(Battery Transpotrion Information) - Certificate of safety of transported goods.

But first, in order for us to have an understanding of what we are talking about, let's find out what these lithium batteries are, why they are used everywhere and where did they come from?

If you are not interested in all this thenyou can go to the information regarding the UN rules.

Battery

A battery is two or more electrical elements connected in parallel or in series. Electrical elements are connected in order to obtain a greater voltage removed from the battery (with a serial connection), or a greater current or capacity (with a parallel connection). Usually, this term refers to the connection of electrochemical sources of electric current of galvanic cells and electric batteries.

The progenitor of the battery is considered to be the voltaic column, invented by Alessandro Volta in 1800, consisting of sequentially connected copper-zinc galvanic cells.

Usually, a battery is usually not quite correctly called single galvanic cells (for example, type AA or AAA), which are usually connected to a battery in the battery compartments of equipment to obtain the necessary voltage.

Next, let's analyze the concept of an electric battery.

Electric battery

An electric battery is a chemical current source, a reusable EMF source, the main specificity of which is the reversibility of internal chemical processes, which ensures its repeated cyclic use (through charge-discharge) for energy storage and autonomous power supply of various electrical devices and equipment, as well as for providing backup energy sources in medicine, manufacturing, transport and in other areas.

The very first battery was created in 1803 by Johann Wilhelm Ritter. Its battery consisted of a column of fifty copper circles, between which a wet cloth was laid. After passing current from the voltaic column through this device, it itself began to behave as a source of electricity.

The principle of operation of the battery is based on the reversibility of a chemical reaction. The battery's operability can be restored by charging, that is, by passing an electric current in the direction opposite to the direction of the current during discharge. Several batteries combined into one electrical circuit make up the battery. As the chemical energy is exhausted, the voltage and current drop, the battery ceases to function. You can charge the battery (battery of accumulators) from any DC source with a high voltage with current limitation.

Since this article is considering lithium batteries, then we will continue to write about elements containing lithium.

Lithium cell

The lithium cell is a single non-rechargeablegalvanic cell, in which lithium or its compounds are used as an anode. The cathode and electrolyte of a lithium cell can have many types, so the term "lithium cell" combines a group of elements with the same anode material.

It differs from other batteries by high operating time and high cost. Depending on the selected size and the chemical materials used, a lithium battery can produce a voltage of 1.5 V (compatible with alkaline cells) or 3.0 V. Lithium batteries are widely used in modern portable electronic equipment.

Lithium-metal cells are galvanic cells in which lithium metal or lithium compounds are used as an anode. Lithium metal also includes lithium alloy batteries. Unlike other lithium-containing batteries, which have an output voltage of more than 3 V, lithium-metal batteries have two times less. In addition, they cannot be recharged. In these batteries, the lithium anode is separated from the iron-sulfide cathode by an electrolyte layer, this sandwich is packed in a sealed case with micro valves for ventilation.

This technology represents a compromise that the developers made to ensure the compatibility of lithium power supplies with equipment designed for the use of alkaline batteries, and was conceived as a competitor to alkaline batteries. Compared to them, lithium-metal ones weigh a third less, have a larger capacity, and, in addition, they are also stored longer. Even after ten years of storage, they retain almost all of their charge.

Lithium-metal cells have found application in devices that place high demands on batteries over a long service life, such as an electrocardiostimulator and other implantable medical devices. Such devices can operate autonomously for up to 15 years.

Next, we will talk in detail about electric batteries and consider only lithium-ion batteries.

Lithium-ion battery

A lithium-ion battery is a rechargeable battery in which lithium is present only in ionic form in the electrolyte. This category also includes lithium polymer cells.

A lithium-ion battery consists of electrodes (cathode material on aluminum foil and anode material on copper foil) separated by a porous separator impregnated with electrolyte. The package of electrodes is placed in a sealed housing, the cathodes and anodes are connected to the terminals-current collectors. The housing is sometimes equipped with a safety valve that relieves internal pressure in case of emergency situations or violations of operating conditions.

For the first time, the fundamental possibility of creating lithium batteries based on the ability of titanium disulfide or molybdenum disulfide to include lithium ions when the battery is discharged and extract them when charging was shown in 1970 by Michael Stanley Whittingham. A significant disadvantage of such batteries was the low voltage - 2.3 V and high fire hazard due to the formation of lithium metal dendrites closing the electrodes. Later, J. Gudenaf synthesized other materials for the lithium battery cathode - lithium cobaltite LixCoO2 (1980), lithium ferrophosphate LiFePO4 (1996). The advantage of such batteries is a higher voltage - about 4 V. A modern version of a lithium-ion battery with a graphite anode and a lithium cobalt cathode was invented in 1991 by Akira Yoshino. The first lithium-ion battery according to his patent was released by Sony Corporation in 1991.

Lithium-ion battery is very widespread in modern household electronics and finds its application as an energy source in electric vehicles and energy storage devices in energy systems. This is the most popular type of batteries in devices such as cell phones, laptops, digital cameras, video cameras and electric vehicles.

Lithium-ion batteries differ in the type of cathode material used. The charge carrier in a lithium-ion battery is a positively charged lithium ion, which has the ability to penetrate (intercalate) into the crystal lattice of other materials (for example, graphite, metal oxides and salts) to form a chemical bond, for example: graphite with the formation of LiC6, oxides (LiMnO2) and salts (LiMnRON) of metals. Lithium-ion batteries are almost always used in a set with a monitoring and control system - a CCU or BMS (Battery Management System), - and a special charge/discharge device.

Design of Lithium-ion batteries

Structurally, Li-ion batteries are produced in cylindrical and prismatic versions. In cylindrical accumulators, a package of electrodes and a separator rolled up in the form of a roll is enclosed in a steel or aluminum housing with which a negative electrode is connected. The positive pole of the battery is brought through the insulator to the cover. Dissimilar electrodes in lithium and lithium-ion batteries are separated by a separator made of porous polypropylene.

Prismatic accumulators are produced by folding rectangular plates on top of each other. Prismatic batteries provide a tighter package in the battery, but it is more difficult to maintain compressive forces on the electrodes in them than in cylindrical ones. In some prismatic batteries, a roll assembly of a package of electrodes is used, which is twisted into an elliptical spiral. This allows you to combine the advantages of the two design modifications described above.

Some constructive measures are usually taken to prevent rapid heating and ensure the safety of Li-ion batteries. Under the battery cover there is a device that reacts to a positive temperature coefficient by increasing resistance, and another that breaks the electrical connection between the cathode and the positive terminal when the gas pressure inside the battery increases above the permissible limit. To improve the safety of operation of Li-ion batteries, external electronic protection must also be used as part of the battery, the purpose of which is to prevent the possibility of overcharging and over-discharging of each battery, short circuit and excessive heating.

Most Li-ion batteries are manufactured in prismatic versions, since the main purpose of Li-ion batteries is to ensure the operation of cell phones and laptops. As a rule, the designs of prismatic batteries are not unified and most manufacturers of cell phones, laptops, etc. do not allow the use of batteries from outside companies in devices.

The design of Li-ion and other lithium batteries, as well as the design of all primary current sources ("batteries") with a lithium anode, is characterized by absolute tightness. The requirement of absolute tightness is determined both by the inadmissibility of leakage of liquid electrolyte (negatively affecting the equipment) and the inadmissibility of oxygen and water vapor from the environment entering the battery. Oxygen and water vapor react with the materials of the electrodes and electrolyte and completely disable the battery.

Technological operations for the production of electrodes and other parts, as well as the assembly of batteries, are carried out in special dry rooms or in sealed boxes in an atmosphere of pure argon. When assembling batteries, sophisticated modern welding technologies, complex designs of hermetic ducts, etc. are used. The laying of active electrode masses is a compromise between the desire to maximize the discharge capacity of the battery and the requirement to guarantee the safety of its operation, which is provided at a ratio of C-/ C + => 1.1 to prevent the formation of lithium metal (and thereby the possibility of ignition).

Explosion hazard

Lithium-ion batteries of the first generation were subject to an explosive effect. This was explained by the fact that in the process of multiple charging/discharging cycles, spatial formations known as (dendrites) appeared - complex crystalline formations of a tree-like branching structure, leading to the closure of the electrodes and, as a consequence, a fire or explosion. This disadvantage was eliminated by replacing the anode material with graphite. Similar processes occurred on the cathodes of lithium-ion batteries based on cobalt oxide in violation of operating conditions (overcharging).

Modern lithium batteries have lost these disadvantages. However, lithium batteries from time to time show a tendency to explosive spontaneous combustion. The intensity of gorenje even from miniature batteries is such that it can lead to serious consequences. Airlines and international organizations are taking measures to restrict the transportation of lithium batteries and devices with them in air transport.

Spontaneous ignition of a lithium battery is very difficult to extinguish by traditional means. In the process of thermal acceleration of a faulty or damaged battery, not only the release of stored electrical energy occurs, but also a number of chemical reactions that release substances to maintain combustion, combustible gases from the electrolyte, and also in the case of non-LiFePO4 electrodes, oxygen is released.Gorenje A flared battery is capable of burning without air access and means of isolation from atmospheric oxygen are unsuitable for extinguishing it.

Moreover, lithium metal actively reacts with water to form a combustible hydrogen gas, therefore extinguishing lithium batteries with water is effective only for those types of batteries where the mass of the lithium electrode is small. In general, extinguishing a lit lithium battery is inefficient. The purpose of extinguishing can only be to reduce the temperature of the battery and prevent the spread of flame.

Plane crashes such as the Asiana Airlines 747 near South Korea in July 2011, UPS 747 in Dubai, UAE in September 2010 and UPS DC-8 in Philadelphia, Pennsylvania in February 2006 were associated with ignition of lithium batteries during flights. Usually these fires are associated with a short circuit of the batteries. Unprotected cells can cause a short circuit when touched, followed by spreading, causing a chain reaction that can release a huge amount of energy.

Lithium batteries can also be subject to "thermal overclocking". This means that if the internal circuit is broken, an increase in the internal temperature may occur. At a certain temperature, the battery cells begin to emit hot gases, in turn increasing the temperature in neighboring cells. This will eventually lead to ignition.

Thus, a large number of batteries creates a significant security threat, which is especially acute when transporting by air. A relatively small incident can lead to a huge uncontrolled fire.

UN Regulations UN3480, UN 3481, UN3090, UN3091

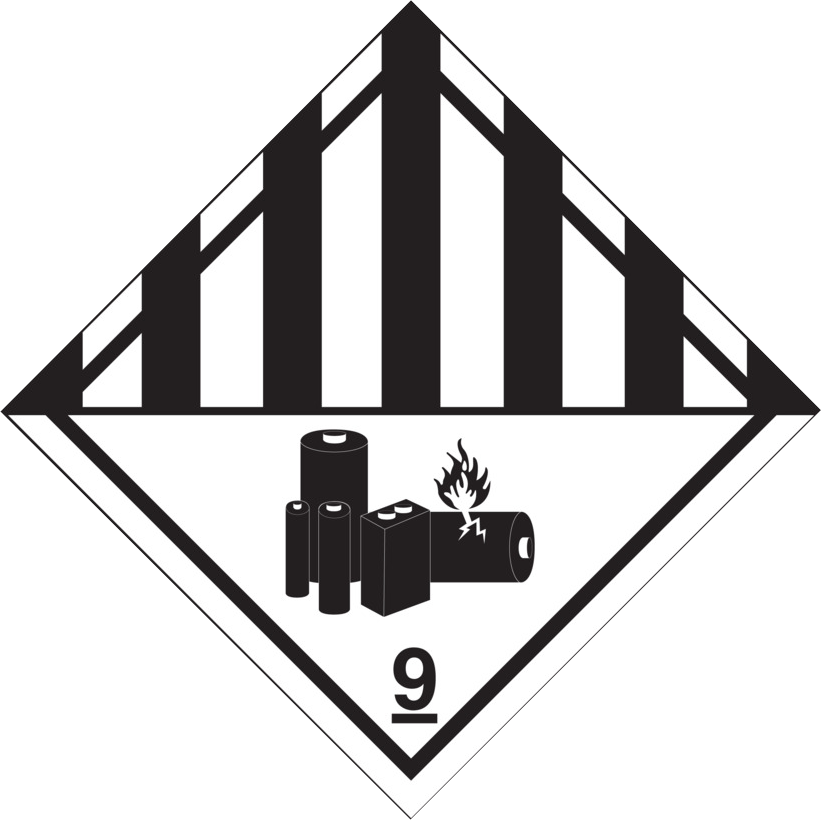

Due to the fact that lithium batteries are potentially extremely dangerous, they are technically classified as materials of Hazard Class 9 - "other dangerous goods" and must be handled, stored and transported accordingly (as specified in UN3480 and additional regulations).

Due to the widespread use and increased risk, the rules for the transportation of lithium batteries have been revised. The danger posed by the transportation of lithium batteries is the possibility of their short circuit, and as a result, most of the legislation focuses on packaging and shipping regulations aimed at reducing the potentially catastrophic consequences of this.

An overview of these rules is as follows:

- Methods of packaging and delivery that exclude the possibility of contact of batteries with each other.

- Methods of packaging and transportation that exclude contact of the battery with a conductive or metallic surface.

- Mandatory verification that all batteries are securely packed to prevent movement (inside the package) during transport, which could potentially cause the terminal covers to loosen or accidentally turn on.

The transportation of lithium batteries is effectively regulated by 4 UN legislative acts, although there are many features in them that may affect the exact process you need to take to ensure safe delivery (or at least minimize the risk as much as possible).

- UN 3090 - Lithium metal batteries (shipped by themselves)

- UN 3480 - Lithium-ion batteries (shipped by themselves)

- UN 3091 - Lithium metal batteries contained in equipment or packed with equipment

- UN 3481 - Lithium-ion batteries contained in the equipment or packed with the equipment.

There are also variousmarking requirementspackaging that will be used to transport lithium batteries. These requirements differ mainly depending on the following 4 factors:

- Are the batteries contained in the supplied equipment (for example, in a watch, calculator or laptop)

- Packed together with the equipment (for example, in a power tool packed together with a spare battery)

- Shipped in small batches (which can be covered in limited quantities - the lowest of the four levels of dangerous goods transportation)

- They are shipped in very small quantities that do not fall under the rules of transportation of dangerous goods at all (for example, two batteries installed in the equipment).

Class 9, Packing group II, tunnel category E, ADR /RID labels 9

Correct shipping name Lithium-ion batteries, UN 3480

ADR special provisions 188, 230, 310, 636 and Packing Instructions P903, P903a and P903b apply.

Damaged and defective batteries: Contact your national competent authority.

If your lithium-ion batteries are being transported by truck for transportation across Europe, you should make sure that you comply with all the requirements set out in the ADR 2017 manual.

In fact, this is a European Agreement that regulates the transportation of lithium batteries by road/land transport (and indeed any dangerous goods).

To transport lithium batteries by rail, it is necessary that you comply with a different set of specific rules for the transportation of dangerous goods. These rules are described in detail in the Manual for the Transport of Dangerous Goods by Rail (RID).

These regulations, combined with ADR guidelines used for road transport, actually require similar packaging, processes and protection.

For more information, visitUNECE website.

Class Packing group II IMO labels 9

Correct shipping name Lithium-ion batteries, UN 3480

Code IMDG: Special provisions 188, 230, 310 and packing instructions P903

EmS: F-A, S-I

Storage category A

Damaged and defective batteries: Contact your national competent authority

Delivery of lithium batteries by sea

If you ship lithium batteries by sea, you need to comply with the International Code for the Transport of Dangerous Goods at Sea (IMDG). This document is updated every two years, which means that Amendment 38-16 of the 2018 edition is the current set of rules.

To familiarize yourself with the rules set out in the IMDG Code, you must purchase a copy of the Code from the International Maritime Organization or cooperate with a freight forwarder who is familiar with these rules.

Class Packing group II ICAO signs 9

Correct shipping Name Lithium-ion batteries, UN 3480

IATA: Special Provisions A88, A99, A154, A164, Packing instructions P965, P966, P967, P968, P969, P970

Damaged and defective batteries/used batteries : Not allowed for air transportation.

Delivery of lithium batteries by air

The delivery of lithium batteries by air is the most difficult of all forms of transit due to the increased risk (i.e. aviation accidents caused by fire can be fatal). Since damaged batteries were previously recognized as the cause of plane crashes, transportation of damaged or defective batteries is strictly prohibited.

When transporting lithium-ion batteries by air, the Dangerous Goods Regulations (DGR) must be observed. These rules are regulated by the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO).

To get acquainted withIATA Guidance Document on Lithium Batteries click here to go to this resource.

Importance of the UN3480 / UN3090 rules

The company or individual engaged in the delivery of lithium batteries bears sole and full responsibility in the event of any accident caused by non-compliance with the rules.

Failure to comply with the rules for packaging lithium batteries that meet the requirements of UN3480 can have serious consequences for your business. This can result in significant fines, jail time for your organization's employees, and reputational damage as a result of a (potentially fatal) accident.

- Views: 47005

- Government Resolution No. 778 dated 07/06/2018

- Which goods are declared as one product

- Government Resolution No. 2240 dated 07.12.2022

- What is required for DS according to TR CU 009/2011

- What is required for CC or DS according to TR CU 004/2011

- What is required for CC or DS according to TR CU 020/2011

- Customs control of the value of goods