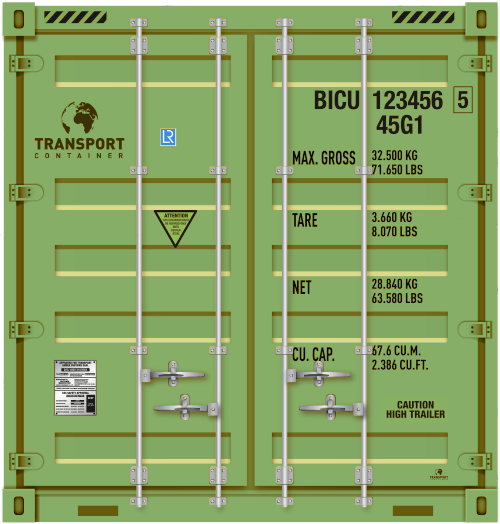

Decoding of designations on containers

ISO6346 is an international standard established by The International Container Bureau for the Coding, Identification and Labeling of Shipping Containers which establishes.

- Container identification system:

- Owner's code, (BIC code)

- Equipment Category ID

- Container serial number

- The check digit

- Size and type code

- Country code

- Operational signs

Container owner code-The code consists of the first three capital letters of the Latin alphabet, serves to designate the main owner or operator of a sea container. Such a code must be registered in International Container Bureau in Paris, providing uniqueness all over the world.

Equipment Category ID -The equipment category identifier consists of one capital letter of the Latin alphabet, which is located immediately after the container owner code:

- U - for all cargo containers

- J - for removable equipment related to cargo containers

- Z - for trailers and chassis

Container number -This is a container serial number consisting of 6 digits designed to uniquely identify the container.

Check digit- A number that is a means of verifying the authenticity of the owner's code and serial number. The control number is related only to the owner's code, the equipment category identifier and the container serial number.

Country code (optional) -The country code consists of two capital letters of the Latin alphabet, as described in the standard ISO 3166. They indicate the country where the code is registered, not the nationality of the owner or operator of the sea container.

Operational tags -Operational tags are designed to transmit the requested information during the transportation of containers or give a visual warning.

Operational tags include:

- Container weight

- A symbol to indicate the surface of the container

- Electrical hazard warning sign

- Container height is higher than 2.6 m (8 ft 6 in)

The security table attached to the container and its purpose.

Since the container is a vehicle for the transportation of goods between States, it has not only standard dimensions, but also the necessary safety for service personnel during transportation. This is achieved by its design and the material used and strength. In confirmation of these facts , the container is attachedKBK plate(Convention on Safe Containers), which is issued by the qualification and supervisory authority of the country.

English is set as the language of filling in the table. The dimensions of the table are 200 * 100 mm. It is made of corrosion-resistant material. It is attached to the left door of the container in its lower part. The container doors themselves also additionally indicate: own mass, maximum massgrossin kilograms and pounds. The KBK plate serves as a guarantee of the container's safety.

In this regard, the container is considered certified for safety for the countries that have signed the CBC. The following information is indicated on the plate:

- The country that granted the approval and the approval number, as shown for example in line 1 (the country that granted the approval should be indicated by the distinguishing sign used to indicate the country of registration of vehicles in international traffic);

- Date (month and year) of manufacture;

- The identification number of the container assigned by the manufacturer, or for existing containers for which this number is unknown, the number assigned by the administration;

- Maximum operating gross weight (kilograms and pounds);

- Permissible weight onstackingat 1.8 g (kilograms and pounds), where g is the acceleration of gravity;

- The magnitude of the load during the transverse structural stiffness test (kilograms and pounds);

- The strength of the end wall is indicated in the plate only if the end walls are designed for a load of less than or more than 0.4 of the maximum permissible payload, i.e. 0.4 P;

- The strength of the side wall is indicated on the plate only if the side walls are designed for a load of less than or more than 0.6 of the maximum permissible payload, i.e. 0.6 P;

- Date (month and year) of the first preventive inspection of new containers and dates (month and year) of subsequent preventive inspections, if the plate is used for this purpose. The countries that have signed the CBC mutually recognize containers with plates certified by national qualification authorities. The volumes and methods of mandatory testing of containers are contained in the ISO standard, as well as in national standards (for example, GOST 20260 of the former USSR).

Tables for determining the size and type of container by the number on the container 4|5|G1

| The first sign | Length m . | Length feet | Inches |

|---|---|---|---|

| 1 | 2.991 | 10 | |

| 2 | 6.068 | 20 | |

| 3 | 9.125 | 30 | |

| 4 | 12.192 | 40 | |

| A | 7.150 | ||

| B | 7.315 | 24 | |

| C | 7.430 | 24 | 6 |

| D | 7.450 | ||

| E | 7.820 | ||

| F | 8.100 | ||

| G | 12.500 | 41 | |

| H | 13.106 | 43 | |

| K | 13.600 | ||

| L | 13.716 | 45 | |

| M | 14.630 | 48 | |

| N | 14.935 | 49 | |

| P | 16.154 |

| Container height | Container width | ||||

|---|---|---|---|---|---|

| THE SECOND SIGN | |||||

| m. | feet | inches | 2.438 m . | > 2.438 m. <2.5 m. | > 2.5 m . |

| 2.438 | 8 | \(zero) | |||

| 2.591 | 8 | 6 | 2 | C | L |

| 2.743 | 9 | 4 | D | M | |

| 2.895 | 9 | 6 | 5 | E | N |

| >2.895 | >9 | 6 | 6 | F | P |

| 4 | 3 | 8 | |||

| Sign | Container type |

|---|---|

| GP | General purpose container without ventilation |

| G0 | One end or both ends are open(s) |

| G1 | Passive ventilation in the upper part of the cargo space |

| G2 | One end (or both ends) is open(s), one (or both) sides are also open |

| G3 | One end (or both ends) are open), also one (or both) sides are not fully open |

| VH | General purpose container with ventilation |

| V0 | Non-mechanical system with ventilation holes in the lower and upper parts of the cargo space |

| V2 | Mechanical ventilation system located inside |

| V4 | Mechanical ventilation system located outside |

| RE-RT-RS | Refrigerated container |

| R0 | Mechanical refrigerator |

| R1 | Mechanical refrigerator with heating |

| R2 | Mechanical refrigerator with its own installation |

| R3 | Mechanical refrigerator with its own installation and heating |

| TO | Container with an opening top |

| U0 | Opens one end (or both ends) open(s) |

| U1 | One end (or both ends) is open(s), there are removable upper elements on the end frames |

| U2 | One end (or both ends) is open(s), one (or both) side walls are open |

| U3 | One end (or both ends) is open, one (or both) side walls are open, there are removable upper elements on the end frames |

| U4 | One end (or both ends) is open(s), one side is not fully open and the other side is fully open |

| U5 | Fully fixed side walls and ends (without doors) |

| TN-TD-TG | Tank container |

| T0 | Non-hazardous liquids, minimum pressure 0.45 bar |

| T1 | Non-hazardous liquids, minimum pressure 1.50 bar |

| T2 | Non-hazardous liquids, minimum pressure 2.65 bar |

| T3 | Hazardous liquids, minimum pressure 1.50 bar |

| T4 | Hazardous liquids, minimum pressure 2.65 bar |

| T5 | Hazardous liquids, minimum pressure 4.00 bar |

| T6 | Hazardous liquids, minimum pressure 6.00 bar |

| T7 | Gases, minimum pressure 9.10 bar |

| T8 | Gases, minimum pressure 22.00 |

| T9 | Gases, with a certain pressure |

| HR-HI | Thermal container |

| H0 | With cooling or heating, with removable equipment located outside; heat transfer coefficient K = 0.4W / M2.K |

| H1 | With cooling or heating, with removable equipment located inside |

| H2 | With cooling or heating, with removable equipment located inside |

| H5 | Heat transfer coefficient K = 0.7W / M2.K |

| H6 | Isothermal. Heat transfer coefficient K = 0.4W / M2.K |

| THIS-BK | Container for transportation of dry bulk cargo |

| B0 | Closed container |

| B1 | Airtight container |

| B3 | Horizontal unloading, test pressure 1.5 bar |

| B4 | Horizontal unloading, test pressure 2.65 bar |

| B5 | Rollover unloading, test pressure 1.5 bar |

| B6 | Rollover unloading, test pressure 2.65 |

| PL-PF-PC-PS | Platform |

| P0 | Container platform |

| P1 | With full rigidly fixed ends |

| P2 | Rigidly fixed racks, free-standing racks or racks with a movable upper element |

| P3 | Folding design |

| P4 | Folding racks, free-standing racks or removable top element |

| P5 | Open top, open ends |

| SN | Special purpose container |

| S0 | Container for transporting livestock |

| S1 | Container for transporting cars |

| S2 | Container for transporting live fish |

- Views: 29555

- Government Resolution No. 778 dated 07/06/2018

- Which goods are declared as one product

- Government Resolution No. 2240 dated 07.12.2022

- What is required for DS according to TR CU 009/2011

- What is required for CC or DS according to TR CU 004/2011

- What is required for CC or DS according to TR CU 020/2011

- Customs control of the value of goods